A new ultra green diesel fuel is now being produced in the Foothills.

Cielo Waste Solutions moved into the old Western Bio-Diesel refinery in Aldersyde and have equipped the facility to create a renewable diesel fuel.

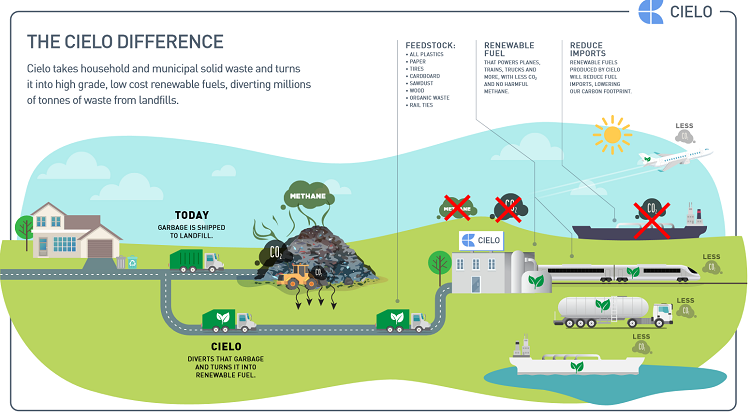

Cielo CEO Don Allan says the best part is their raw materials in the process are found in landfills.

"We tell whoever is managing the landfill to take anything of value out of it, so take your metals, glass, rocks and dirt out if and we'll take the rest." Allan says "We'll take all seven types of plastics, we'll take tires, organics like grass clippings and food waste. We'll take anything made from trees, so paper, cardboard and even railroad ties. We take cloth and basically your entire blue box material."

Allan says it's their goal to completely eliminate the need for a landfill.

The Cielo process is different from the creation of Bio-Diesel, instead Allan calls it "renewable diesel."

"We're making renewable diesel, not bio-diesel, there's a huge difference between the two." Allan says "Bio-Diesel is usually made from Agriculture food crop so things like canola, soy beans, Cargill's animal tallow and yellow grease from restaurants. Naturally they all have a lot of water in them."

According to Allan, in order to meet federal mandates producers must blend fuels like gasoline mixed with ethanol or diesel mixed with bio-diesel. The problem with that and Bio Diesel Allan says comes down to the amount of water in it.

"You can only use bio-diesel in the summer time because there's so much water in it, it freezes in the winter. Our diesel doesn't have water in it and because we're not using food crops, which are right now a very expensive feed stock we can charge people to take their garbage so it's like a negative number for us."

Allan says most importantly their process is renewable.

"We're not dealing with fossil fuels, we actually work with companies like Suncor, Huskey and Shell who need to blend that renewable product into their oil and gas and we sell into that government mandated market."

Recent stories highlight similar processes like that of Sweden who burn their garbage and produce energy to heat their homes, but Allan notes, during that burning process there's a release of methane gas which isn't found in their process.

"Our footprint is so small we can actually sell carbon credits back to bigger emitters so they can keep their numbers down." Allan explains "We burn nitrogen which we create from the air and that's it. There's no harmful emissions at all out of our product."

The garbage, or raw materials (feed stock) are brought into their silo's on a conveyor system where they're mixed into a slurry using used motor oil. Once the landfill waste is mixed with the used motor oil it's preheated and eventually mixed with the catalyst where a process called Catalytic Thermal De-polymerization creates hydrocarbon particles. The catalyst collects the atoms that create diesel and makes it a gas.

Once the product is cooled it's turned into a renewable distillate that create Naphtha, Kerosene and Diesel.

Once processed Ceilo can sell their renewable product to clients.

Cielo has been operating at their Aldersyde refinery using sawdust to perfect their process for about four years now, and have ushered in a new age with their grand opening on July 11, 2019.